Automotive Paint Correction: Complete Guide to Professional Car Paint Restoration

What’s automotive paint correction?

Automotive paint correction is a specialized process that remove surface imperfections from a vehicle’s paintwork through control abrasion techniques. This meticulous procedure eliminate swirl marks, scratches, oxidation, water spots, and other defects that accumulate over time, restore the paint to its original clarity and gloss.

Source: pinterest.com

The process involve use increasingly finer abrasive compounds and polish machines to level the paint surface. Professional detailers employ various techniques and tools to achieve results that oftentimes surpass the vehicle’s original factory finish quality.

Understand paint defects and imperfections

Vehicle paint face constant assault from environmental factors and improper maintenance techniques. Common defects include swirl marks cause by circular washing motions, fine scratches from automatic car washes, water spots from mineral deposits, and oxidation from UV exposure.

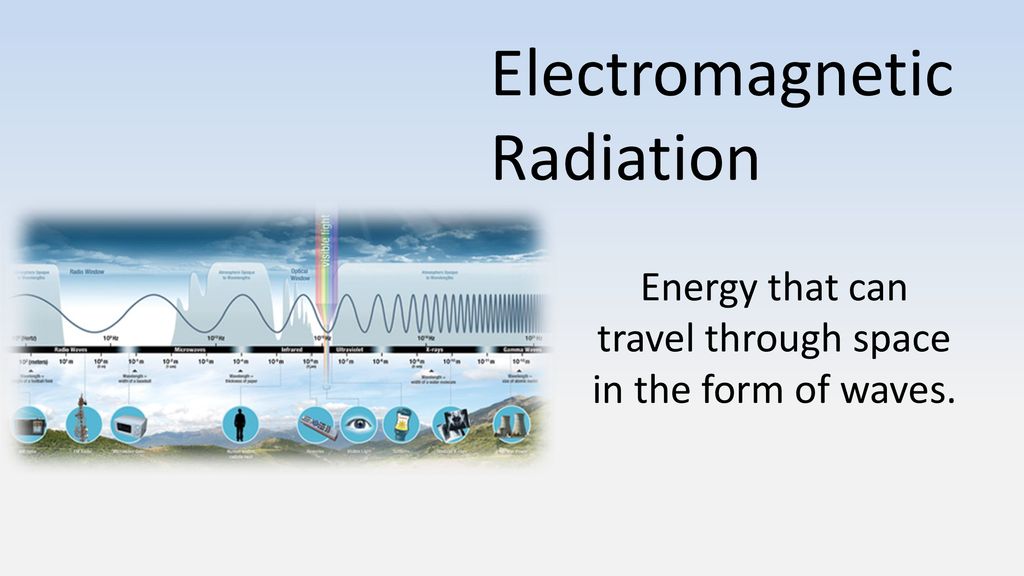

These imperfections occur in the clear coat layer, which protect the colored base coat underneath. The clear coat typically measure between 1.5 to 2.5 mile thick, provide limited material for correction work. Understand this thickness limitation is crucial for determine correction possibilities.

Random isolate deep scratches (rids )require special attention during assessment. These deeper marks may penetrate through the clear coat into the base coat or primer, require different correction approaches or complete panel refinish.

Paint correction process steps

The correction process begins with thorough vehicle preparation. Thisincludese complete washing, decontamination with clay bars or chemical decontaminants, and mask sensitive areas. Proper lighting setup is essentiafor identifyingfy all defects and monitor progress throughout the process.

Paint thickness measurements use electronic gauges determine the available material for correction. These readings guide the selection of appropriate compounds and techniques while ensure sufficient clear coat remain for protection.

The actual correction involve multiple stages use different abrasive levels. Heavy cutting compounds remove deeper defects, follow by medium compounds for refinement, and finish polishes for final clarity and gloss enhancement.

Compound stage

Heavy cutting compounds contain larger abrasive particles design to remove significant defects chop chop. Machine polishers with cut pads apply these compounds under control pressure and speed. The key lie in remove merely enough material to eliminate defects without create additional damage.

Rotary polishers provide maximum cutting power for severe correction needs, while dual action machines offer safer operation for less experienced users. Pad selection affects cut ability, with wool pads provide aggressive correction and foam pads offer more control results.

Polish stage

Medium abrasive polishes refine the surface after heavy cutting, remove the micro marring leave by compounds. This intermediate step prepares the paint for final finishing while address any remain moderate defects.

Multiple polishing stages may be necessary to depend on the initial paint condition and desire final results. Each stage use increasingly finer abrasives to achieve smoother surface finishes.

Finishing stage

Final finish polishes contain the finest abrasives or no abrasives’ astatine completely, focus on maximize gloss and clarity. These products remove the last traces of micro mar while enhance the paint’s reflective properties.

Jeweling compounds and glazes may be used in this stage to achieve show quality finishes. The goal iscreatedan a utterly smooth surface that reflect light uniformly across the entire panel.

Tools and equipment for paint correction

Professional paint correction require specialized equipment beyond basic detail supplies. Machine polishers form the foundation of any correction setup, with rotary and dual action models serve different purposes.

Rotary polishers spin in a single direction, provide consistent power delivery ideal for heavy correction work. These machines require more skill to operate safely but offer superior cutting ability for challenge defects.

Dual action polishers combine rotation with orbital motion, reduce the risk of paint damage while even provide effective correction capability. These machines are more forgiving for beginners while ease capable of professional results.

Pads and accessories

Correction pads come in various materials and densities to match different correction stages. Wool pads provide maximum cutting ability, microfiber pads offer excellent defect removal with less heat generation, and foam pads provide control correction with vary aggressiveness levels.

Pad selection must match the compound or polish being use, with manufacturers oft provide compatibility guides. Use incorrect pad and product combinations can reduce effectiveness or create additional defects.

Paint thickness gauges measure clear coat depth earlier and during correction, prevent over correction that could damage the paint system. Digital calipers and various measuring tools help maintain consistent technique across panels.

Paint correction levels and classifications

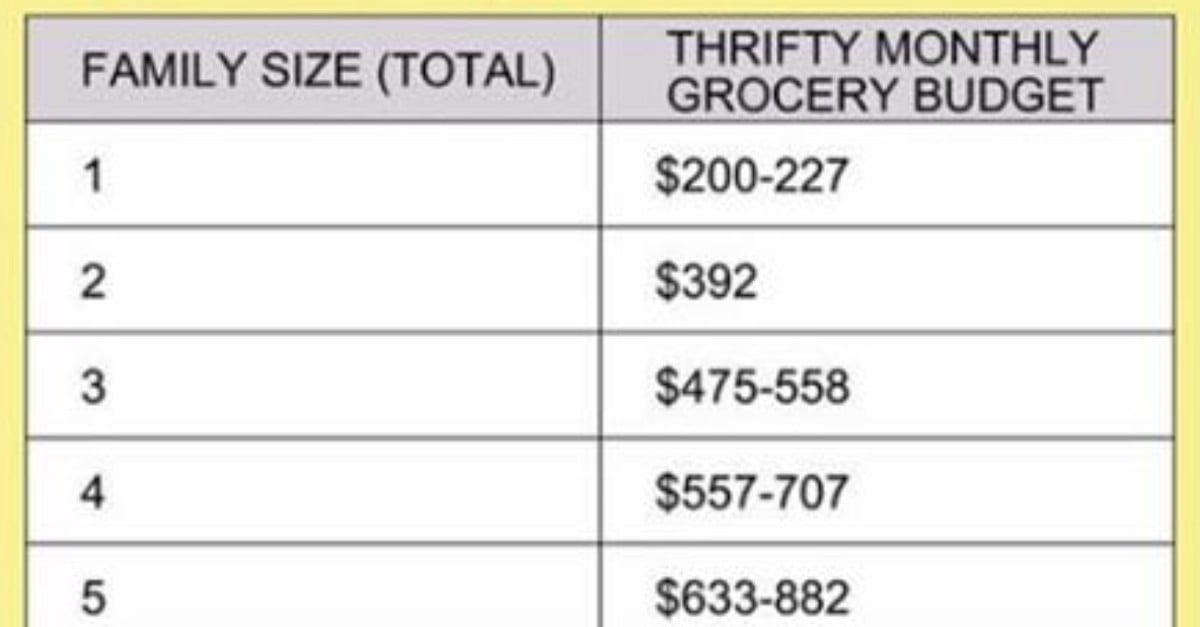

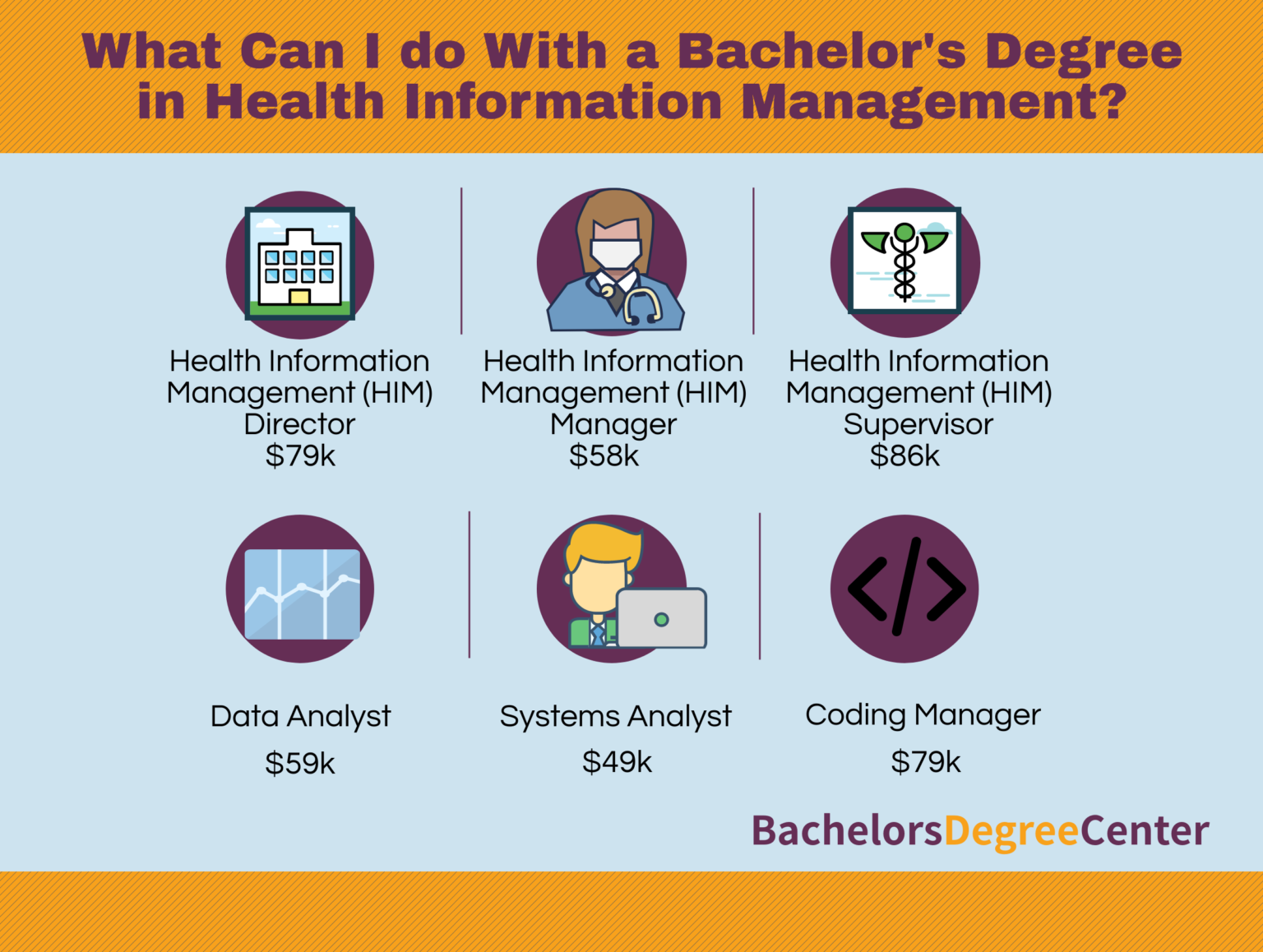

The detail industry recognizes different correction levels base on defect removal percentages and final finish quality. These classifications help customers understand service expectations and pricing structures.

Single stage correction typically remove 60 80 % of defects use one compound and polish combination. This level address the virtually visible imperfections while provide significant improvement at a moderate cost.

Two stage correction achieve 85 95 % defect removal through separate compounding and polish steps. This approach provide excellent results for most vehicles while maintain reasonable time and cost requirements.

Multi-stage correction can achieve 95 99 % defect removal through multiple compounding and polish steps. This level produce show quality finishes but require importantly more time and expertise.

Paint types and correction considerations

Different paint systems respond otherwise to correction techniques. Single stage paints combine color and protection in one layer, while modern clear coat systems separate these functions into distinct layers.

Clear coat paints dominate current automotive production, provide superior protection and gloss retention. These systems allow for more aggressive correction since defects typically occur merely in the clear coat layer.

Specialty paints like metallics, pearls, and ceramics require modify correction approaches. These paints may show different defect patterns and require specific techniques to avoid create new problems during correction.

Age and hardness factors

Paint hardness affect correction difficulty and technique selection. Softer paints correct easier but may show defects more promptly after completion. Harder paints require more aggressive approaches but typically maintain results farseeing.

Paint age influences hardness, with newer paints oftentimes being softer and more responsive to correction. Older paints may have cure to extreme hardness, require specialized techniques and products.

Professional vs DIY paint correction

Professional paint correction services provide expertise, equipment, and guarantee that DIY approaches oftentimes can not match. Experienced technicians understand paint systems, proper techniques, and how to avoid costly mistakes.

Professional facilities offer control environments with proper lighting, ventilation, and temperature control. These conditions are essential for achieve consistent, high quality results across all panels.

DIY correction can be rewarding and cost-effective for enthusiasts willing to invest in proper equipment and education. Yet, the learn curve is steep, and mistakes can be expensive to repair.

Source: lokiautocosmetics.com

Cost considerations

Professional correction services range from several hundred to several thousand dollars depend on vehicle size, paint condition, and desire results. This investment oftentimes prove worthwhile for valuable vehicles or when guarantee results are essential.

DIY correction require significant upfront equipment investment but provide ongoing value for multiple vehicles or regular maintenance. Quality machines, pads, and products represent substantial initial costs.

Maintenance after paint correction

Proper maintenance preserve correction results and extend the time between future correction needs. This includes use proper washing techniques, quality products, and protective measures.

Two bucket washing methods, microfiber towels, and pH neutral shampoos minimize the introduction of new defects. Avoid automatic car washes and circular washing motions help maintain the correct finish.

Paint protection films, ceramic coatings, or traditional waxes provide barriers against environmental damage. These products help preserve the correct finish while make future maintenance easier.

Regular inspection and touch ups

Regular paint inspection identify new defects before they become severe problems require full correction. Early intervention with spot correction techniques maintain overall finish quality.

Professional maintenance programs oftentimes include periodic inspections and minor correction work to keep vehicles look their best. These services cost less than full correction while maintain superior appearance.

Advanced paint correction techniques

Wet sanding represent the virtually aggressive correction technique, use fine abrasive papers with water lubrication to remove severe defects. This technique require exceptional skill and should solely be attempted by experienced professionals.

Spot correction addresses isolate defects without treat entire panels, save time and preserve surround paint. This technique require precise blending to avoid create visible repair areas.

Panel painting may be necessary when defects are overly severe for correction or when insufficient clear coat remain. This option provide complete restoration but require color matching and blend expertise.

Quality control and final inspection

Proper lighting is essential for final inspection, reveal any remain defects or correction marks. Multiple light sources at different angles ensure comprehensive evaluation of the finished work.

Paint thickness measurements after correction document the remain clear coat thickness and verify that safe limits were maintained throughout the process.

Final inspection include check for hologram effects, buffer trails, or other correction induce defects that require additional attention. Professional standards demand perfect results across all treat surfaces.

Paint correction transform vehicle appearance while preserve and extend paint system life. Whether perform professionally or as a DIY project, proper correction techniques restore automotive finishes to exceptional condition while provide last satisfaction for vehicle owners.

MORE FROM jobsmatch4u.com