Automotive Batteries: Understanding Hazard Classifications and Safety Considerations

Automotive batteries and hazard classifications

Automotive batteries are essential components in vehicles, provide the electrical energy need to start engines and power electrical systems. Yet, these power sources come with inherent risks that require proper classification and handling. Understand the hazard class of automotive batteries is crucial for transportation, storage, and disposal.

What hazard class are automotive batteries?

Automotive batteries are classified as

Class 8 hazardous materials

, which designate them as

Corrosive materials

. This classification is mainly due to the sulfuric acid electrolyte contain within lead acid batteries, the near common type use in vehicles.

The department of transportation (dot )and the unUnited Nationsglobally harmonized system of classification and labeling of chemicals ( (sGHS)th recognize automotive batteries under this classification because of their potential to cause severe damage to live tissue and corrode metals upon contact.

Source: automotivean.com

Why automotive batteries are classified as corrosive materials

The corrosive designation stem from several characteristics of automotive batteries:

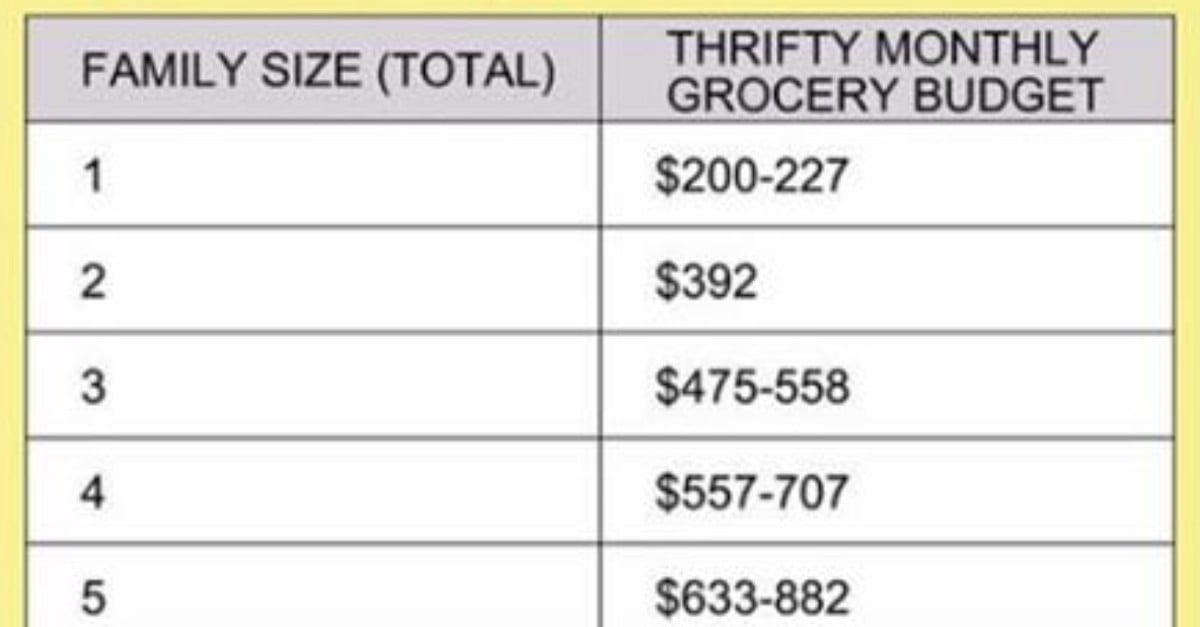

Source: fromhungertohope.com

-

Sulfuric acid content

lead acid batteries contain a solution of sulfuric acid, which can cause chemical burns to skin and eyes -

pH level

the electrolyte solution is extremely acidic, with a ppHtypically between 1 and 2 -

Reaction with metals

the acid can corrode many metals, potentially damage equipment or surround materials -

Potential for leakage

damage batteries may leak acid, create hazardous conditions

During normal operation, these corrosive materials are safely contained within the battery casing. Notwithstanding, damage, improper handling, or disposal can lead to exposure of these hazardous components.

Secondary hazard classifications for automotive batteries

While the primary classification is class 8 corrosive, automotive batteries may too present additional hazards:

Environmental hazards

Lead acid batteries contain materials that are environmentally harmful, include:

-

Lead

a toxic heavy metal that can contaminate soil and water -

Acid

can alter the ppHof soil and water bodies, harm ecosystems -

Other metals

may contain small amounts of other potentially harmful metals

Due to these environmental concerns, automotive batteries are oftentimes subject to special disposal regulations and recycling programs.

Potential for hydrogen gas generation

During charge and discharging, lead acid batteries can produce hydrogen gas, which is extremely flammable. In confine spaces with poor ventilation, this gas can accumulate and create an explosion hazard if ignite by a spark or flame.

This secondary hazard is why battery storage areas require proper ventilation and why smoking or open flames should ne’er be permitted near charge batteries.

Regulatory framework for automotive battery hazards

Several regulatory bodies govern the classification, handling, and transportation of automotive batteries:

Department of transportation (dot )regulations

The dot regulate the transportation of hazardous materials, include automotive batteries, under title 49 of the code of federal regulations (49 cCFR) Specific provisions include:

-

Packaging requirements

batteries must be package to prevent short circuits and damage -

Labeling requirements

packages must display the class 8 corrosive label -

Documentation

proper shipping papers must accompany battery shipments -

Special provisions

certain exemptions may apply to undamaged batteries in vehicles or when right protect

Environmental protection agency (eEPA)regulations

The EPA regulate the disposal and recycling of automotive batteries under the resource conservation and recovery act (rCRA))Key provisions include:

-

Universal waste rule

simplifies the management of certain hazardous wastes, include batteries -

Recycling requirements

encourage the recycling of lead acid batteries -

Disposal restrictions

prohibit the disposal of lead acid batteries in landfills in many states

Occupational safety and health administration (oOSHA)regulations

OSHA regulations address workplace safety concerns relate to automotive batteries:

-

Hazard communication

require proper labeling and safety data sheets -

Personal protective equipment

specifies appropriate protection for workers handle batteries -

Emergency procedures

outlines response protocols for battery acid spill or exposures

Safety precautions when handle automotive batteries

Due to their classification as corrosive materials, automotive batteries require specific safety precautions:

Personal protective equipment (pPPE)

When handle automotive batteries, particularly if there be a risk of leakage or damage, the follow PPE is recommended:

-

Chemical resistant gloves

to protect hands from acid contact -

Eye protection

safety glasses or face shields to prevent eye exposure -

Protective clothing

aacid-resistantaprons or coveralls for extensive handling -

Proper footwear

closed toe shoes to protect feet from accidental spills

Handle procedures

Safe handling practices include:

-

Proper lifting techniques

use battery carriers or lift with your legs, not your back -

Prevent short circuits

ne’er place metal tools across battery terminals -

Ventilation

ensure adequate airflow when charge batteries -

No smoking or open flames

eliminate ignition sources near batteries -

Secure installation

decent secure batteries in vehicles to prevent movement

Emergency response for battery acid exposure

If exposure to battery acid occur:

-

Skin contact

instantly flush with cool, run water for astatine least 15 minutes -

Eye contact

flush eyes with water for astatine least 15 20 minutes while hold eyelids open -

Inhalation

move to fresh air and seek medical attention -

Ingestion

do not induce vomiting; seek immediate medical attention -

Neutralization

for spills, use bake soda to neutralize acid before cleanup

Different types of automotive batteries and their hazards

While traditional lead acid batteries are the near common, other types of automotive batteries present different hazard profiles:

Lead acid batteries

These traditional automotive batteries contain:

-

Lead plates

toxic if ingest or if dust is iinhaled -

Sulfuric acid electrolyte

extremely corrosive -

Plastic casing

loosely resistant to acid but can crack or break

Lead acid batteries include both flood (with liquid electrolyte )and seal varieties, with sealed versions reduce but not eliminate the risk of acid leakage.

Absorbent glass mat (aAGM)batteries

AGM batteries are a type of lead acid battery with these characteristics:

-

Electrolyte absorption

acid is aabsorbedin a glass mat separator -

Reduced leakage risk

less likely to leak than flooded batteries -

Static classify as corrosive

despite reduce risk, yet fall under class 8

Lithium-ion batteries

Progressively use in electric and hybrid vehicles, lithium-ion batteries present different hazards:

-

Fire risk

can ignite if damage or improperly charge -

Thermal runaway

can experience uuncontrolledtemperature increases -

Different hazard class

oftentimes classify as class 9 ((iscellaneous hazardous materials ))

The growth use olithium-ionon batteries in automotive applications has lead to new safety protocols and regulations specific to these battery types.

Transportation and shipping requirements

As class 8 corrosive materials, automotive batteries have specific requirements for transportation:

Ground transportation

For highway transportation within the United States:

-

Packaging

batteries must be secure to prevent short circuits and damage -

Label

packages must display the corrosive label -

Shipping papers

must include proper shipping name, hazard class, un identification number, and quantity -

Exceptions

some exceptions exist for batteries iinstallin vehicles or equipment

Air transportation

Air shipment of automotive batteries is more restrictive:

-

Passenger aircraft

most automotive batteries are pprohibitedon passenger aircraft -

Cargo aircraft

may be transport with proper packaging and documentation -

IATA regulations

must comply with international air transport association dangerous goods regulations

International shipping

International transportation must comply with:

-

IMG code

international maritime dangerous goods code for sea transport -

Country specific regulations

destination countries may have additional requirements -

Declaration forms

proper hazardous materials declarations must accompany shipments

Storage requirements for automotive batteries

Proper storage is essential to minimize hazards associate with automotive batteries:

Facility requirements

-

Ventilation

adequate airflow to prevent hydrogen gas accumulation -

Temperature control

ideally between 40 ° f and 80 ° f (( ° c and 27 ° c )) -

Acid-resistant flooring

concrete or other aacid-resistantsurfaces -

Spill containment

secondary containment to capture potential leaks -

Fire protection

appropriate fire extinguishers and suppression systems

Storage practices

-

Upright position

store batteries upright to prevent leakage -

Terminal protection

cover terminals to prevent short circuits -

Separation

keep batteries aside from incompatible materials -

Inventory management

use first in, first out rotation -

Inspection

regular checks for damage, leakage, or bulging

Disposal and recycling of automotive batteries

Due to their hazardous components, automotive batteries require proper disposal:

Recycling process

Automotive batteries are among the nearly recycled products, with a recycling rate exceed 95 % in the United States. The recycling process typically includes:

-

Collection

batteries are collect at retailers, repair shops, or recycling centers -

Break

batteries are break isolated in a hammer mill -

Separation

components are separate into lead, plastic, and acid -

Process

each component is process for reuse -

Manufacture

recycled materials are uusedto produce new batteries

Legal requirements

Legal disposal requirements vary by location but loosely include:

-

Prohibition on landfill disposal

most states ban automotive batteries from landfills -

Retailer take back programs

many states require retailers to accept used batteries -

Deposit systems

some areas impose a deposit that’s refund upon battery return -

Documentation

businesses may need to maintain records of proper disposal

Emergency response for battery relate incidents

Proper emergency response is critical for incidents involve automotive batteries:

Acid spills

For battery acid spills:

-

Evacuation

clear the area of unnecessary personnel -

Protection

use appropriate pPPEfor cleanup -

Neutralization

apply bake soda or commercial neutralizers -

Containment

prevent acid from enter drains or waterways -

Disposal

collect neutralized material for proper disposal

Fire response

For battery relate fires:

-

Class d fire extinguishers

for metal fires in lithium batteries -

Water or ABC extinguishers

for lead acid battery fires -

Ventilation

ensure adequate ventilation to disperse hydrogen gas -

Professional response

large incidents may require hazmat team response

Conclusion

Automotive batteries are classified as class 8 corrosive materials due to the sulfuric acid electrolyte they contain. This classification carry significant implications for handling, transportation, storage, and disposal. Understand these hazards and follow proper safety protocols is essential for anyone who work with or around automotive batteries.

By recognize the corrosive nature of these power sources and take appropriate precautions, the risks associate with automotive batteries can be efficaciously managed. Proper handling not solely protect individuals from potential harm but besides help safeguard the environment through responsible recycling and disposal practices.

Whether you’re a professional automotive technician, a vehicle owner, or involve in battery transportation or recycling, awareness of these hazard classifications and safety requirements is crucial for prevent accidents and ensure compliance with relevant regulations.

MORE FROM jobsmatch4u.com